Why Choose A Gate Valve Over A Ball Valve For Flow Control

2025-09-01

When it comes to flow control in pipeline systems, one common question we encounter is whether to use a gate valve or a ball valve. While both have their advantages, the choice ultimately depends on the application. In many industrial settings, a gate valve is preferred for its reliability and performance under specific conditions.

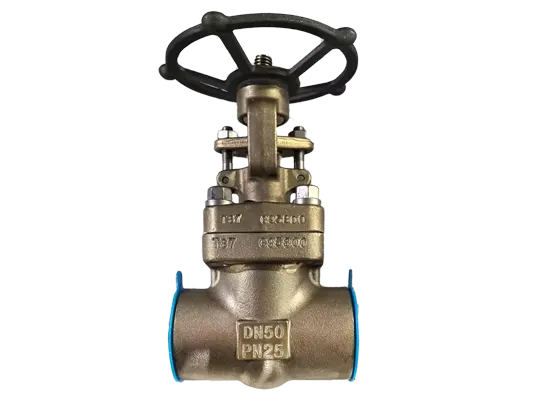

At LYV®, we have engineered high-performance gate valves that excel in applications requiring full flow or complete shut-off. Unlike ball valves, which are ideal for quick on/off operation, gate valves provide a tight seal and minimal pressure drop when fully open. This makes them particularly suitable for high-pressure and high-temperature environments.

Key Advantages of LYV® Gate Valves

-

Low Pressure Drop: When fully open, the gate retracts completely into the bonnet, allowing straight-line flow with minimal resistance.

-

Tight Sealing: The wedge-shaped disc provides excellent sealing in both directions, reducing the risk of leakage.

-

Durability: Manufactured from robust materials such as ASTM A216 WCB, our valves withstand demanding conditions.

-

Bi-Directional Flow: Suitable for applications where flow direction may change.

Technical Specifications of LYV® Gate Valves

| Feature | Specification |

|---|---|

| Pressure Range | Up to 300 PSI |

| Temperature | -20°F to 400°F |

| Operation Type | Handwheel, Gear, or Actuated |

| End Connection | Flanged, Socket Weld, Threaded |

Frequently Asked Questions About Gate Valves

What is the primary function of a gate valve

A gate valve is designed for on/off control rather than flow regulation. It should be used either fully open or fully closed to avoid erosion of the disc and seats.

Can a gate valve be used for throttling

No. Using a gate valve for throttling can cause vibration and damage to the sealing surfaces due to partial opening. For throttling, globe or control valves are more suitable.

How does a gate valve compare to a ball valve in high-pressure applications

Gate valves are often preferred in high-pressure systems because of their ability to provide a tighter seal and lower pressure drop when fully open compared to ball valves.

For more technical details or assistance in selecting the right valve for your application, our experts at LYV® are ready to help.

Contact us today to discuss your requirements or request a product demonstration.