What Materials Are Swing Check Valves Typically Made From

2026-01-09

When specifying a Swing Check Valve for your piping system, selecting the correct material is not just a detail—it's a critical decision that determines the valve's performance, longevity, and cost-effectiveness. The material must withstand the fluid's corrosive properties, pressure, and temperature. At Jinqiu, we understand that this choice is fundamental to system integrity. This guide will explore the typical materials used in constructing Swing Check Valves to help you make an informed selection.

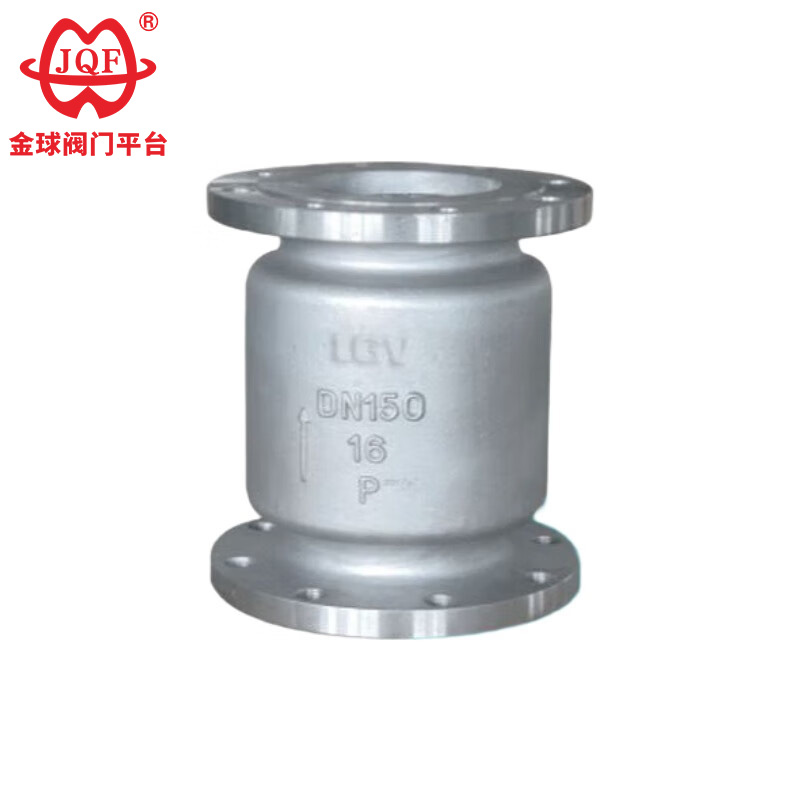

The body and disc, the primary components of a Swing Check Valve, are manufactured from a variety of materials, each suited for specific service conditions.

Common Body and Disc Materials:

-

Cast Iron: Economical and durable for non-corrosive applications like water, oil, or gas in low to medium pressure systems.

-

Ductile Iron: Offers greater strength and impact resistance than cast iron, suitable for higher pressure scenarios.

-

Carbon Steel: Ideal for high-pressure and high-temperature services, commonly used in steam, oil, and gas pipelines.

-

Stainless Steel: The go-to choice for corrosive environments, offering excellent resistance to a wide range of chemicals and high temperatures.

-

Bronze/Brass: Excellent for seawater, freshwater, and certain chemical services due to good corrosion resistance and machinability.

-

Alloy 20 & Duplex Stainless Steels: Used for highly aggressive corrosive fluids in chemical processing, petrochemical, and marine applications.

Critical Trim Components:

The hinge pin, seat, and disc seal often use different materials than the body to ensure tight sealing and smooth operation.

| Component | Typical Materials | Purpose |

|---|---|---|

| Hinge Pin | Stainless Steel, Monel | Provides strength and corrosion resistance for the swinging mechanism. |

| Seat Ring | Stainless Steel, PTFE, EPDM, Buna-N | Creates the sealing surface; elastomers like EPDM ensure bubble-tight shut-off. |

| Disc Seal | Metal (Stainless), Resilient (Rubber) | Metal for high temp, resilient seals for tighter shut-off on liquids. |

Swing Check Valves FAQ

What is the main advantage of a stainless steel Swing Check Valve?

The primary advantage is exceptional corrosion resistance. Stainless steel Swing Check Valves from Jinqiu can handle everything from aggressive chemicals and solvents to saltwater and high-purity water, ensuring a long service life with minimal maintenance in harsh environments.

Can the sealing material in a Swing Check Valve be customized?

Absolutely. While standard valves come with default seals like EPDM or Nitrile, Jinqiu often customizes the seal material based on the specific fluid. For example, we may recommend Viton for hydrocarbon-based fluids or PTFE for highly corrosive acids to ensure optimal performance and leak-proof sealing.

How does material choice affect the pressure rating of the valve?

The material's inherent strength directly dictates its pressure capability. A cast iron valve is suitable for lower pressure classes, while a carbon steel or forged stainless steel Swing Check Valve is engineered to withstand much higher system pressures. Always consult the manufacturer's pressure-temperature rating charts for the specific material grade.

Choosing the wrong material can lead to premature valve failure, costly downtime, and safety risks. The experts at Jinqiu combine decades of material science knowledge with practical application experience to guide you. We don't just sell valves; we provide reliable flow solutions built with the right materials for your unique challenge.

Contact us today with your application details—fluid, pressure, temperature, and line size—and let our engineering team recommend the perfect Swing Check Valve material for your system's reliability and efficiency.