What Makes Trunnion Mounted Ball Valve Essential for Industrial Applications?

2026-01-12

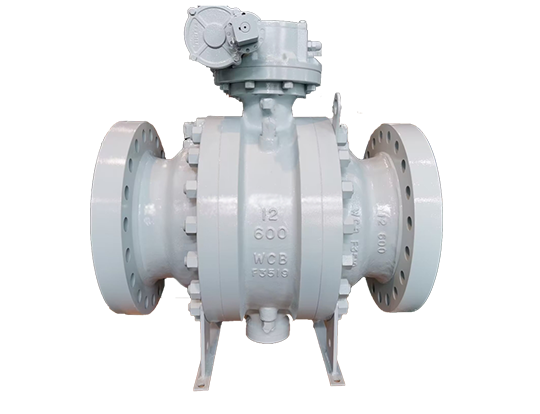

In the modern industrial sector, controlling the flow of liquids and gases efficiently is paramount. One of the most reliable solutions is the Trunnion Mounted Ball Valve, widely used in oil & gas, petrochemical, and water treatment industries. Zhejiang Liangyi Valve Co., Ltd. specializes in manufacturing high-quality valves that guarantee durability, performance, and safety.

The Trunnion Mounted Ball Valve stands out due to its unique design. Unlike floating ball valves, the ball in a trunnion-mounted valve is supported by a trunnion at the top and bottom, which reduces stress on the seats and enables smooth operation under high pressure. This design ensures long-term reliability and lower torque requirements, which is crucial for automated operations.

How Does Trunnion Mounted Ball Valve Work?

The operation of a trunnion-mounted ball valve is straightforward yet efficient. Here's a quick overview:

-

Ball Support: The ball is fixed at the top and bottom (trunnion), ensuring stability.

-

Sealing: Seats are spring-loaded to maintain contact with the ball, providing a tight seal even at high pressure.

-

Actuation: Can be manually operated or connected to pneumatic/electric actuators for automation.

-

Flow Control: Provides precise control with minimal leakage, suitable for critical applications.

Comparison Table: Trunnion Mounted vs Floating Ball Valve

| Feature | Trunnion Mounted Ball Valve | Floating Ball Valve |

|---|---|---|

| Ball Support | Top & bottom trunnion | Only supported by seats |

| Torque Requirement | Low | High at high pressure |

| Pressure Handling | Up to 2500 psi+ | Limited |

| Application | High-pressure pipelines | Low to medium pressure |

| Durability | High | Moderate |

Why Choose Trunnion Mounted Ball Valve?

-

High Performance Under Pressure: The trunnion design ensures the valve handles extremely high pressures without seat damage.

-

Reduced Operational Torque: Compared to floating ball valves, these valves require less force to operate, making automation more efficient.

-

Safety and Reliability: Leakage is minimized due to spring-loaded seats, which is vital in chemical and petrochemical industries.

-

Longevity: Designed to withstand harsh environments, reducing maintenance costs.

Applications of Trunnion Mounted Ball Valve

Zhejiang Liangyi Valve Co., Ltd. manufactures valves suitable for a variety of industries:

-

Oil & Gas: For pipeline flow control and isolation.

-

Petrochemical Plants: Handling corrosive and high-pressure fluids.

-

Water Treatment: Reliable flow control in municipal water systems.

-

Power Plants: Steam and gas pipeline isolation with minimal leakage.

Key Benefits List:

-

Reduced maintenance frequency

-

Enhanced flow control precision

-

Cost-efficient automation

-

Long service life under high pressure

Best Practices for Using Trunnion Mounted Ball Valve

-

Ensure regular inspection of seats and seals.

-

Choose the correct actuator type based on operation requirements.

-

Maintain proper lubrication to reduce wear.

-

Select valve materials compatible with media to prevent corrosion.

In conclusion, Trunnion Mounted Ball Valve from Zhejiang Liangyi Valve Co., Ltd. is an ideal solution for industries requiring robust, high-performance flow control. Its design ensures reliability, reduces operational torque, and offers long-lasting service even under extreme conditions.

For customized solutions or bulk orders, contact us today to discover how our valves can enhance your industrial operations efficiently.