What Makes a Check Valve Essential for Your Hydraulic System?

2025-12-08

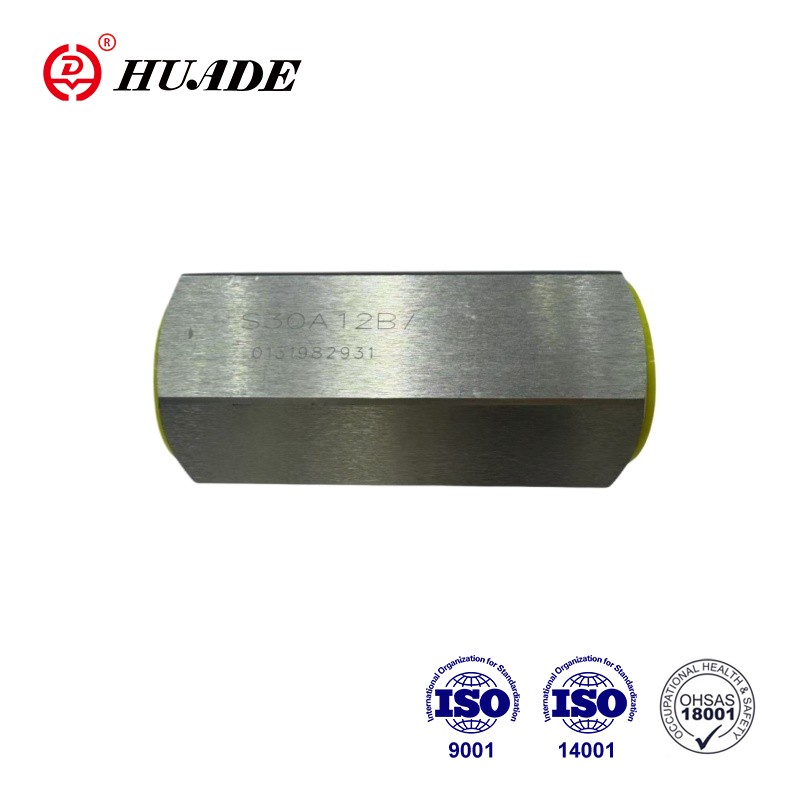

In modern hydraulic systems, ensuring fluid flows efficiently in one direction is critical. That's where the Check Valve comes into play. A check valve is a mechanical device designed to allow fluid to flow in one direction only, preventing backflow and protecting pumps, compressors, and other sensitive components. At Jiangsu Huafilter Hydraulic Industry Co., Ltd., we specialize in high-quality check valves that enhance system reliability and performance. I often ask myself, how can a simple device like a check valve have such a significant impact on hydraulic efficiency? The answer is straightforward: by controlling flow direction and preventing reverse movement, it reduces wear, avoids contamination, and ensures consistent system operation.

How Does a Check Valve Work in Practice?

When I first started working with hydraulic systems, I was curious: how does a check valve actually prevent backflow? Essentially, a check valve consists of a valve body, a movable disk, or a ball that responds to fluid pressure. When fluid flows in the intended direction, the pressure pushes the valve open. If flow reverses, the valve closes automatically, preventing backflow. This simple mechanism ensures equipment longevity and reduces maintenance costs. Here's a quick overview of common types:

| Check Valve Type | Application | Advantages |

|---|---|---|

| Swing Check Valve | Large pipelines, low-pressure flow | Durable, simple design |

| Ball Check Valve | Hydraulic lines, chemical systems | Fast response, minimal leakage |

| Lift Check Valve | High-pressure systems | Precise sealing, reliable |

| Diaphragm Check Valve | Food, pharmaceutical, water systems | Hygienic, corrosion-resistant |

Why Should I Choose Jiangsu Huafilter Hydraulic Industry Co., Ltd. for Check Valves?

I asked myself this question when selecting suppliers: why should I rely on Jiangsu Huafilter Hydraulic Industry Co., Ltd. for check valves? The reasons are clear. Our check valves are manufactured with high-quality materials, precision engineering, and rigorous testing to ensure consistent performance. Additionally, we offer customized solutions tailored to your hydraulic system requirements, whether for industrial machinery, water treatment, or chemical processing. Choosing a reliable supplier ensures fewer system failures, longer equipment lifespan, and reduced operational costs.

Key Benefits of Using Check Valves:

-

Prevents Backflow: Protects pumps, compressors, and other critical components.

-

Reduces Maintenance: Minimizes wear and tear from reverse flow.

-

Ensures System Efficiency: Maintains smooth and consistent hydraulic operation.

-

Enhances Safety: Avoids pressure surges and fluid contamination.

-

Versatile Applications: Suitable for water, oil, chemical, and food industries.

Check Valve vs. Other Flow Control Devices

Understanding the difference between check valves and other flow control devices is essential for optimal system design. Here's a comparative view:

| Feature | Check Valve | Gate Valve | Ball Valve |

|---|---|---|---|

| Flow Direction Control | Automatic, one-way | Manual, bi-directional | Manual, bi-directional |

| Response Time | Instant | Slow | Moderate |

| Maintenance | Low | Medium | Medium |

| Application | Hydraulic, chemical, water | Pipeline isolation | On/off control |

My Experience with Check Valves in Hydraulic Systems

When I reflect on my experience, I often wonder: which type of check valve is best for high-pressure hydraulic systems? Based on practical usage, lift check valves or ball check valves provide the most reliable performance under high-pressure conditions. Their precise sealing and rapid response prevent system damage, offering peace of mind for operators. Meanwhile, for larger pipelines with moderate pressure, swing check valves are cost-effective and durable.

In conclusion, investing in a quality check valve from Jiangsu Huafilter Hydraulic Industry Co., Ltd. is not just a matter of equipment choice; it's a decision that ensures safety, efficiency, and longevity of your hydraulic systems. Whether you need standard solutions or customized designs, we are committed to delivering excellence.

Contact us today to find the ideal check valve for your system and experience unmatched hydraulic performance.