What Is A Single Seat Control Valve?

2025-08-29

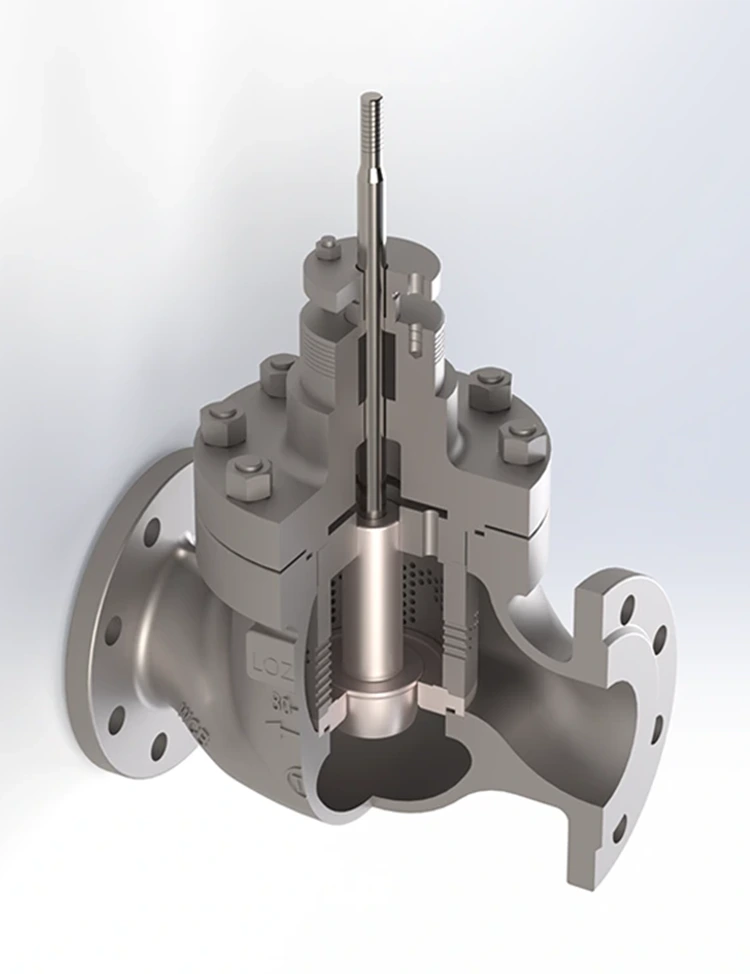

A single seat control valve is a fundamental component designed to regulate the flow, pressure, or level of a medium within a piping system. At its core, it consists of a valve body, a single plug and seat assembly, and an actuator. The defining characteristic is its one seating surface, which allows for tight shut-off capabilities, making it ideal for applications where leakage is unacceptable. Our factory specializes in engineering these valves to meet the most demanding conditions, ensuring optimal performance and longevity.

Key Features and Design Principles

The effectiveness of a single seat control valve stems from its straightforward yet robust design. The plug, connected to the valve stem, moves relative to the stationary seat, altering the flow area. This movement is precisely controlled by an actuator, which responds to signals from a process controller.

Key design features include:

1. Tight Shut-off: The single-seat design provides excellent sealing, often achieving leakage rates classified as Class IV or higher.

2. Precision Control: These valves offer fine modulation of flow, making them suitable for processes requiring accurate control.

3. Simplicity: With fewer internal components compared to more complex designs, they are generally easier to maintain and repair.

4. Versatility: They can handle a wide range of fluids, including gases, liquids, and even steam, across various temperatures and pressures.

Our design philosophy focuses on enhancing these inherent features to deliver superior products.

Technical Parameters of Our Conventional Series Control Valve

To understand the capability of a single seat control valve, examining its technical specifications is crucial. Our Shuka Conventional Series Control Valve is engineered for high performance and durability. Below is a detailed breakdown of its standard parameters.

Table: Conventional Series Control Valve Technical Specifications

| Parameter Category | Specification Details |

| Valve Size (DN) | 15, 20, 25, 32, 40, 50, 65, 80, 100 |

| Pressure Rating (PN) | 16, 25, 40, 63, 100 |

| Connection Type | Flanged (RF, RTJ), Threaded (NPT, BSP) |

| Body Material | Carbon Steel (WCB), Stainless Steel (CF8, CF8M, CF3, CF3M) |

| Trim Material | Stainless Steel (304, 316, 316L), Hardened Alloys |

| Temperature Range | -196°C to +550°C (depending on materials and packing) |

| Leakage Class | ANSI Class IV (standard), Class VI (available upon request) |

| Flow Characteristic | Linear, Equal Percentage, Quick Opening |

These parameters form the foundation of our product offering. We understand that every application is unique, which is why our Shuka team provides custom solutions, tailoring the Conventional Series Control Valve to meet specific process requirements, ensuring a perfect fit for your system.

Frequently Asked Questions (FAQ)

Q1: What are the main advantages and disadvantages of a single seat control valve?

The primary advantage is its ability to provide very tight shut-off, which is critical in preventing product loss or ensuring safety in many processes. It also allows for precise flow control and has a relatively simple design for maintenance. The main disadvantage is that the unbalanced design creates inherent forces on the valve stem. This requires a larger actuator to overcome these forces, especially in high-pressure drop applications, which can increase the overall cost and size of the assembly compared to a balanced design like a double-seated valve.

Q2: In which applications are single seat control valves most commonly used?

Single seat control valves are the preferred choice in a vast array of industries wherever tight shut-off is a priority. Common applications include controlling steam for heating systems, regulating coolant flow in chemical processing, managing fuel gas lines, and handling make-up water in power generation. They are also extensively used in the oil and gas industry, pharmaceutical manufacturing, and food and beverage processing. Our valves, particularly the Conventional Series Control Valve, are built to perform reliably in these challenging environments.

Why Choose Our Solutions

Our commitment to excellence is evident in every valve we produce. We utilize advanced manufacturing techniques and rigorous quality control checks to ensure that every component meets our high standards. From selecting the raw materials to the final testing phase, our focus is on delivering a product that guarantees performance and durability. Our expertise allows us to offer not just a product, but a complete solution tailored to provide long-term value and reliability for your operations. Ready to enhance your system’s efficiency and reliability? Lozose and partner with Zhejiang Lozose Intelligent Control Instrument Co., Ltd. for expert guidance and superior control valve solutions. Contact our team today to discuss your specific application needs.