What Is a Check Valve and Why Is It Essential in Modern Hydraulic Systems?

2026-01-09

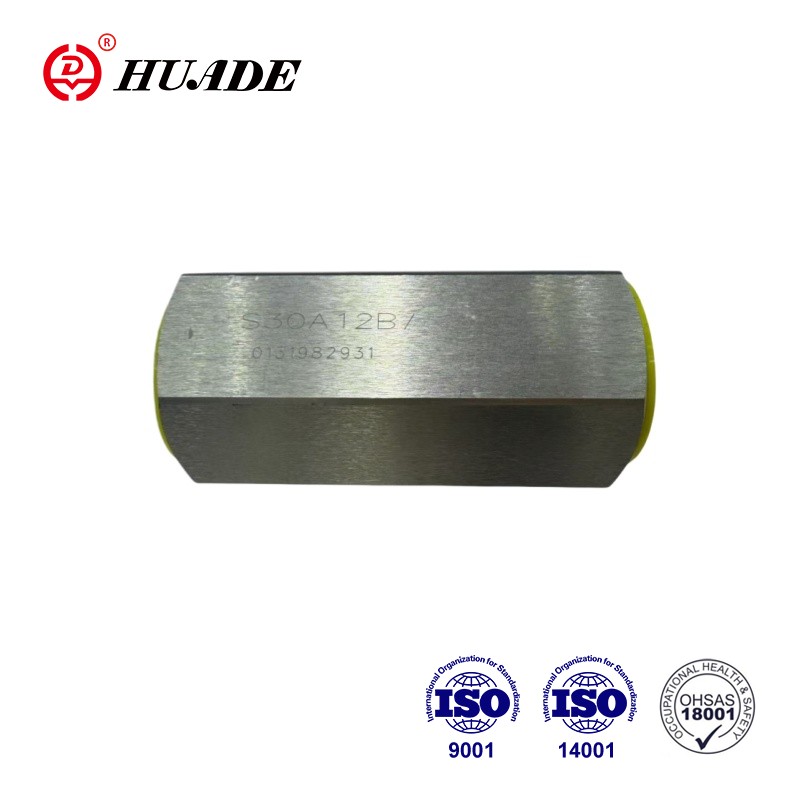

In hydraulic and fluid control systems, ensuring that media flows in only one direction is critical for safety, efficiency, and equipment longevity. A Check Valve is a simple yet indispensable component designed precisely for this purpose. Widely used in hydraulic, pneumatic, water, oil, and industrial pipeline systems, check valves help prevent backflow, protect pumps and compressors, and maintain stable system pressure. At Jiangsu Huafilter Hydraulic Industry Co., Ltd., we specialize in manufacturing high-performance check valves engineered for reliability, durability, and demanding industrial applications.

What Is a Check Valve?

A Check Valve, also known as a non-return valve or one-way valve, is a mechanical device that allows fluid to flow in one direction while automatically preventing reverse flow. It operates without external control, relying on pressure differences within the system.

Basic Working Principle

-

Forward pressure opens the valve

-

Reverse pressure forces the valve closed

-

Prevents backflow and system damage

Types of Check Valve vs Their Applications

Different systems require different check valve designs. Below is a simple comparison:

| Check Valve Type | Key Feature | Typical Application |

|---|---|---|

| Ball Check Valve | Simple structure, low cost | Water & low-pressure systems |

| Spring Check Valve | Fast response, compact | Hydraulic & pneumatic systems |

| Swing Check Valve | Low flow resistance | Large-diameter pipelines |

| Lift Check Valve | Good sealing performance | High-pressure industrial use |

At Jiangsu Huafilter Hydraulic Industry Co., Ltd., we offer customized check valve solutions tailored to specific pressure ranges, media types, and installation conditions.

What Is the Main Function of a Check Valve?

The core function of a Check Valve is to prevent reverse flow, but its role extends far beyond that:

Key Functions

-

Protect pumps and motors from backflow damage

-

Maintain system pressure stability

-

Prevent fluid contamination

-

Reduce water hammer and pressure shocks

How Does a Check Valve Improve System Performance?

Using a high-quality Check Valve significantly enhances the overall efficiency and safety of fluid systems.

Usage Effects

-

✅ Longer equipment service life

-

✅ Reduced maintenance costs

-

✅ Improved operational safety

-

✅ Stable and reliable flow control

In hydraulic systems, even a brief backflow can cause severe component wear. A precision-engineered check valve eliminates this risk effectively.

Why Is a Check Valve So Important in Hydraulic Systems?

The importance of a Check Valve lies in its ability to act as a passive safety guard. Without it, reverse flow could lead to:

-

Pump failure

-

Seal damage

-

Pressure loss

-

System downtime

For industries such as manufacturing, energy, construction, and automation, system reliability directly impacts productivity. That is why selecting the right check valve supplier is crucial.

Which Check Valve Should You Choose?

When selecting a Check Valve, consider the following factors:

-

Operating pressure and temperature

-

Fluid type (oil, water, gas, chemical media)

-

Installation space

-

Response speed requirements

Jiangsu Huafilter Hydraulic Industry Co., Ltd. provides professional technical support to help customers choose the most suitable check valve for their application, ensuring optimal performance and compliance with international standards.

Why Choose Jiangsu Huafilter Hydraulic Industry Co., Ltd.?

-

Advanced manufacturing technology

-

Strict quality control system

-

Wide range of hydraulic check valves

-

Custom OEM & ODM services

-

Global export experience

Our check valves are designed to meet the rigorous demands of modern industrial systems while offering excellent cost-performance value.

Conclusion

A Check Valve may appear simple, but it plays a vital role in protecting equipment, improving system efficiency, and ensuring operational safety. Choosing a reliable, high-quality check valve from a trusted manufacturer can make a significant difference in system performance and long-term costs.

If you are looking for dependable and professionally engineered check valve solutions, Jiangsu Huafilter Hydraulic Industry Co., Ltd. is your trusted partner.

👉 Contact us today to learn more about our products and how we can support your hydraulic system needs.