What Are The Main Differences Between Rising Stem And Non Rising Stem Gate Valves

2025-09-01

When selecting a gate valve for your industrial application, one key decision is choosing between a rising stem and a non-rising stem design. Understanding the differences can help you optimize performance, maintenance, and space considerations.

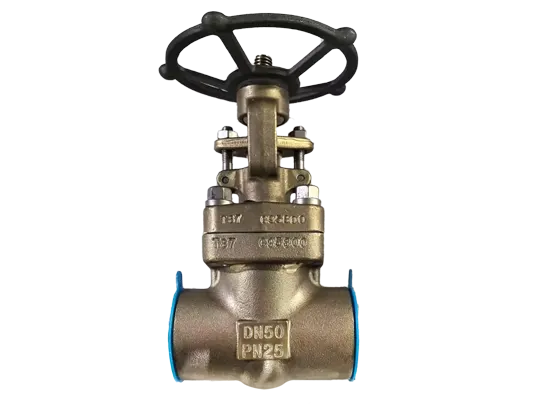

The primary distinction lies in the visual indication of valve position and mechanical operation. In a rising stem gate valve, the stem moves upward as the valve is opened, providing clear visual confirmation. In contrast, a non-rising stem gate valve has a stem that rotates in place without ascending, making it suitable for limited space environments.

LYV® offers both types, manufactured to international standards with superior materials. Key parameters for our gate valves include:

-

Pressure Rating: ANSI 150 to 600

-

Temperature Range: -29°C to 425°C

-

Size Range: 2" to 24"

-

Material: Carbon Steel, Stainless Steel, Duplex

-

End Connection: Flanged, Buttweld, Socket Weld

Here’s a technical comparison:

| Feature | Rising Stem Gate Valve | Non-Rising Stem Gate Valve |

|---|---|---|

| Visual Indication | Yes | No |

| Space Requirement | More | Less |

| Maintenance | Easier | More Complex |

| Typical Use | Above-ground Systems | Underground or Tight Spaces |

Frequently Asked Questions About Gate Valves

Which type of gate valve is better for corrosive environments

For corrosive services, non-rising stem gate valves are often preferred as the stem threads are isolated from the medium. LYV® offers valves in stainless steel or duplex materials for enhanced corrosion resistance.

Can a rising stem gate valve be used in underground installations

It is not recommended. Exposure to dirt and moisture can impede the stem’s movement. Non-rising stem valves are better suited for such applications.

How do I maintain a non-rising stem gate valve

Regular lubrication and occasional bench testing are advised. Since the stem does not exit the valve body, internal inspection might be needed if operational issues occur.

For over two decades, LYV® has been a trusted provider of industrial valving solutions. Our engineers can help you select the right gate valve type for your specific system requirements, ensuring reliability and longevity.

Contact us today for technical support or to request a detailed quotation tailored to your project needs.