What Are the Common Types of Air Control Valves Used in Industrial Applications

2026-01-08

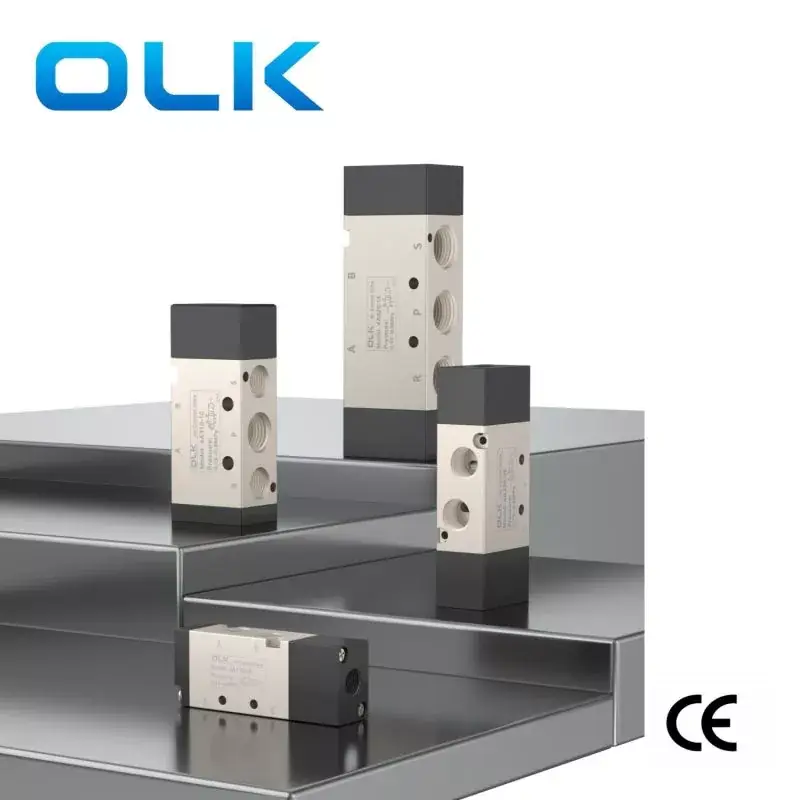

In the complex world of industrial automation and fluid power, precise air management is paramount. The Air Control Valve is a critical component in these systems, directing the flow, pressure, and direction of compressed air to actuate cylinders, tools, and machinery. Selecting the right valve type directly impacts efficiency, reliability, and safety. As a leader in pneumatic solutions, Ouleikai provides a comprehensive range of high-performance valves designed to meet diverse industrial demands. This guide explores the most common types and their applications.

The primary types of Air Control Valves can be categorized by their function and internal mechanism. Here are the most prevalent ones:

-

Directional Control Valves: These are the most common, used to start, stop, or change the direction of airflow. They are often defined by their number of ports and switching positions (e.g., 3/2, 5/2).

-

Flow Control Valves: These regulate the speed of an actuator by controlling the flow rate of air entering or exiting it.

-

Pressure Control Valves: This category includes pressure relief, reducing, and sequence valves, which manage and maintain specific pressure levels within a system.

-

Solenoid Valves: These are electrically operated directional valves, offering precise digital control and integration with PLC systems.

For a clearer comparison of directional valves, a core specialty at Ouleikai, consider the following table:

| Valve Type (Ports/Positions) | Primary Function | Common Industrial Application |

|---|---|---|

| 2/2 Valve | Simple on/off flow control | Basic shut-off for air lines, priming systems |

| 3/2 Valve | Controls a single-acting cylinder | Clamping, ejection, piloting larger valves |

| 5/2 Valve | Controls a double-acting cylinder | Driving cylinders for push/pull, lift/lower motions |

| 5/3 Valve | Controls double-acting cylinder with mid-position | Holding an actuator in a stopped mid-position safely |

Air Control Valve FAQ

What is the main difference between a direct-acting and a pilot-operated solenoid valve?

Direct-acting valves use the solenoid's magnetic force directly to open or close the orifice, suitable for low flow rates. Pilot-operated valves use system pressure to assist in shifting the main valve, making them ideal for higher flow and pressure applications while consuming less electrical power.

How often should industrial air control valves be maintained?

Maintenance intervals depend heavily on operating conditions like cycle rate, air quality, and environmental contaminants. A general best practice is to inspect valves every 6-12 months, checking for seal wear, coil integrity, and proper lubrication if required. Using high-quality filters and dry air significantly extends service life.

Can a faulty air control valve cause other system problems?

Absolutely. A malfunctioning Air Control Valve can lead to erratic actuator movement, loss of pressure, reduced system efficiency, and increased energy consumption. It can also cause downstream damage by allowing moisture or contaminants to pass, or by creating unsafe machine cycling.

Understanding these fundamental valve types is the first step in optimizing your pneumatic systems. For applications requiring durability, precision, and seamless integration, partnering with a trusted provider is key. The experts at Ouleikai are dedicated to helping you select the perfect Air Control Valve for your specific challenge, ensuring peak performance and longevity.

Contact us today to discuss your application requirements and discover the reliable Ouleikai difference in pneumatic control.