What Are The Common Check Valve Problems

2025-10-28

A Check Valve seems like a simple component, but its failure can cause major system downtime, water hammer, and even costly damage. Understanding common Check Valve problems is the first step toward prevention. As an industry veteran, I often see the same issues recurring, many of which can be solved by choosing a superior product from the start.

What Are the Most Frequent Check Valve Failies

Most failures stem from a few key areas. Recognizing these symptoms can help you diagnose issues quickly.

-

Premature Wear and Failure: This is often caused by selecting the wrong valve material for the application, leading to corrosion or erosion from aggressive media.

-

Leaking or Reverse Flow: The valve fails to seal properly. Common causes are a worn seat, a damaged disc, or debris trapped in the sealing surface.

-

Water Hammer: A violent shockwave through the pipes. This occurs when a Check Valve slams shut too quickly due to a lack of damping, often from a missing spring or incorrect valve type for the flow conditions.

-

Noisy Operation (Chattering): A rattling sound typically indicates the valve disc is oscillating. This happens when the valve is installed in a system with low flow velocity that cannot hold it fully open.

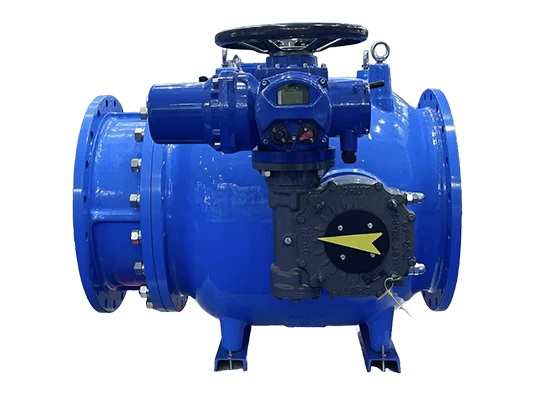

Why LYV® Check Valves Are Engineered for Reliability

At LYV®, we design our valves to overcome these very challenges. Our LYV® Silent Check Valve range isn't just a component; it's a durability solution.

Key Features of our LYV® Check Valve:

-

Robust Spring-Assisted Design: Ensures swift, controlled closure to prevent water hammer.

-

Wide Material Selection: Bodies in forged brass or stainless steel, with seals like NBR or EPDM, to match your specific media.

-

Streamlined Flow Path: Minimizes turbulence and pressure drop, enhancing efficiency.

| Parameter | LYV-200S Specification | Benefit |

|---|---|---|

| Size Range | 1/2" to 2" | Fits most residential and commercial applications. |

| Pressure Rating | 150 PSI (Max 300 PSI) | Withstands system pressure spikes. |

| Body Material | Forged Brass | Superior corrosion resistance and longevity. |

Frequently Asked Questions About Check Valves

What is the main purpose of a Check Valve

The primary purpose of a Check Valve, or non-return valve, is to allow fluid flow in one direction only. It automatically opens with forward flow and closes to prevent reverse flow, protecting equipment like pumps and compressors from damage.

How do I know if my Check Valve has failed

Signs of a failed Check Valve are often clear. You may hear a loud banging (water hammer) at shutdown, notice a reverse flow in the system, see visible leaks from the valve body, or experience a significant loss of system performance and pressure.

Can a Check Valve be repaired or does it need replacement

While some industrial Check Valve models allow for seat and disc replacement, most compact valves like the LYV® series are designed as cartridge units or sealed assemblies. For guaranteed long-term performance and to avoid unplanned downtime, replacement is typically the most reliable and cost-effective solution.

Stop Troubleshooting and Start Solving

Don't let recurring Check Valve problems disrupt your operations and drain your maintenance budget. Investing in a correctly specified LYV® Check Valve from the outset ensures system integrity, reduces noise, and eliminates the risk of water hammer.

Contact us today to discuss your application. Our experts will help you select the perfect LYV® valve to solve your specific challenges for good.