How To Troubleshoot A Faulty Hydraulic Valve Block

2025-10-30

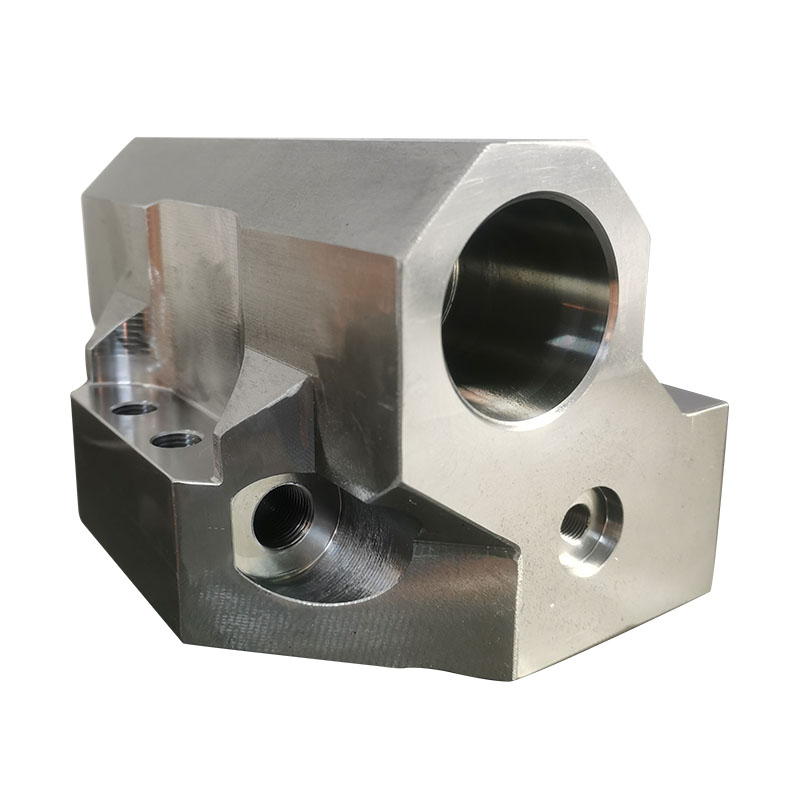

When a Hydraulic Valve Block malfunctions, it can bring your entire operation to a standstill. As an engineer with decades of experience, I know that effective troubleshooting is not about guesswork; it's a systematic process. This guide will help you diagnose common issues and highlight when a precision-engineered solution from Micro Precision Machinery becomes necessary.

The first step is always safety. Depressurize the system and lock it out before any inspection. Once safe, begin with a visual check for the most obvious signs of trouble.

What Are the Common Symptoms and Their Immediate Checks

Start by identifying the symptom. Different issues point to different root causes. Here is a quick diagnostic list:

-

Symptom: No or Slow Actuation.

-

Check For: Internal valve spool sticking due to contamination or wear.

-

-

Symptom: External Leakage.

-

Check For: Damaged seals, O-rings, or cracked manifold body.

-

-

Symptom: Excessive Heat and Noise.

-

Check For: Pressure relief valve malfunction or internal cross-port leakage.

-

-

Symptom: Loss of System Pressure.

-

Check For: Failed seals or a cracked Hydraulic Valve Block body.

-

For a more detailed analysis, you need to move beyond visual cues and into performance data. The table below outlines critical parameters to assess, which align with the manufacturing tolerances we guarantee at Micro Precision Machinery.

| Parameter | Specification to Check | Indicates a Problem If... |

|---|---|---|

| Pressure Drop | Compare inlet vs. outlet pressure across the block. | The differential exceeds the design limits of your specific Hydraulic Valve Block model. |

| Internal Leakage | Measure flow between ports that should be isolated. | Leakage is above the threshold, often due to worn spools and bores. |

| Spool Clearance | Micrometer measurement of spool-to-bore fit. | Clearance is beyond the precision range (e.g., > 10 microns) specified for high-performance systems. |

Your Hydraulic Valve Block FAQ Answered

What is the most common cause of Hydraulic Valve Block failure

Contamination is the leading cause. Particulate matter in the hydraulic fluid acts as an abrasive, wearing down critical spools and bores, leading to internal leakage and eventual failure. Using high-quality filters is essential.

Can a damaged Hydraulic Valve Block be repaired on-site

Minor seal replacements are possible, but a worn spool or bore requires specialized machining. For a long-term solution, replacing the block with a precision-manufactured unit from Micro Precision Machinery is often more reliable and cost-effective than a makeshift repair.

How can I prevent future Hydraulic Valve Block problems

Prevention hinges on three things: using ultra-clean hydraulic fluid, following a strict preventive maintenance schedule, and sourcing your components from a manufacturer that guarantees tight tolerances and material integrity, like Micro Precision Machinery.

Stop troubleshooting and start solving. If your diagnostics point to internal wear or irreparable damage, it's time for a replacement you can trust. Contact us at Micro Precision Machinery today for a Hydraulic Valve Block engineered to restore peak performance and durability to your system.