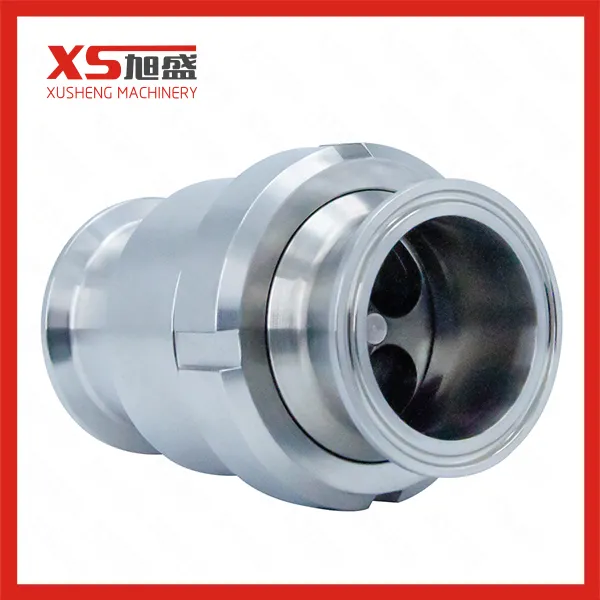

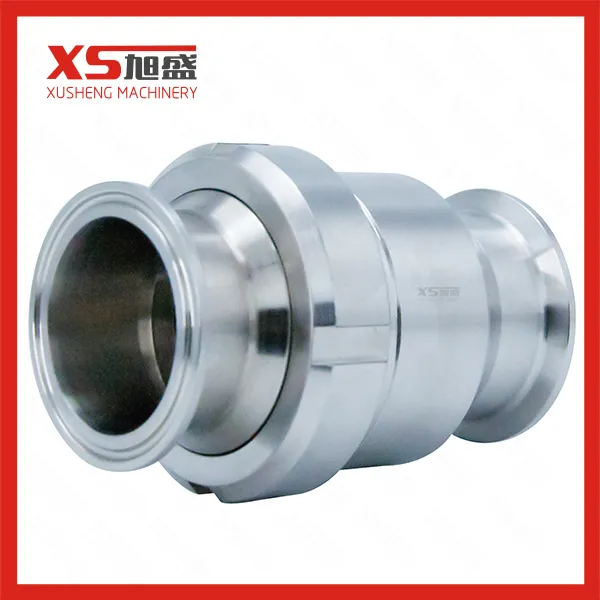

900lb/1500lb Forged Steel Welded Bonnet Piston Check Valve (GAH61H)

Forged Steel Pressure Seal Swing Check Valve Class 900-2500. Standard specification.Design and manufacture:API 602,BS 5352,ANSI B16.34.Connection ends conform to: -Socket welded ends:ANSI B16.11. -(NPT threaded)Screw ends:ANSI B1.20.1. -Butt-welded ends:ANSI B 16.25. -Flanged ends:ANSI B......

Send Inquiry

Product Description

Forged Steel Pressure Seal Swing Check Valve Class 900-2500.

Standard specification.Design and manufacture:API 602,BS 5352,ANSI B16.34.

Connection ends conform to:

-Socket welded ends:ANSI B16.11.

-(NPT threaded)Screw ends:ANSI B1.20.1.

-Butt-welded ends:ANSI B 16.25.

-Flanged ends:ANSI B 16.5.

Inspection & testing:API 598.

NACE MR 0175 on request

Tag: MSS SP 25.

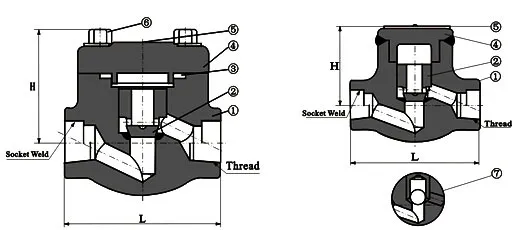

Construction features.

Spring Loaded To Ensure That Even In The Low-Pressure Sealing Performance As Well.

Y pattern straight-through flow path,greatly reducing flow resistance.

Product Range.

Port:Full Port(FP)/Reduced Port(RP).

Structure:BC(Bolted Cover),WC(Welded Cover),PSC(Pressure Self-sealing Cover).

Disc:Swing type,Piston type or Ball type.

Rating: Class 150/ 300/ 600/ 800/ 900/ 1500/ 2500.

Size Range:3/8" to 2".

End Options: FLG, SW(Socket Welded), Threaded(NPT/BSP), BW(Butt Welded),

Optional Materials:

-Carbon Steel: A105, LF2

-Stainless Steel: F304, F304L, F316, F316L

-Duplex: F51, F55

-Alloy: F1, F5, F5A, F9, F11, F22

Special Design:

-Y pattern forged check valve.

Application.

For valves which size is smaller than 2"(DN50), forged steel valves are recommended. Compared with castings,forged valve offer the advantages of more uniform structure, greater density, higher strength integrity, enhanced dimensional characteristics and closer dimensional tolerances.Owing to so many advantageds,the forged valve can be widely used in the fields of petroleum,natural gas,chemical,power and other industries.

Main Parts Material.

| No | Part Name | Material | |||

| 1 | Body | A105 | A182 F22 | A182 F304(L) | A182 F316(L) |

| 2 | Disc | A276 420 | A276 304 | A276 304(L) | A276 316(L) |

| 3 | Gasket | 316+graphite | 316+PTFE | ||

| 4 | Bonnet | A105 | A182 F22 | A182 F304(L) | A182 F316(L) |

| 5 | Nameplate | SS | |||

| 6 | Bolt | A193 B7 | A193 B16 | A193 B8(M) | A193 B8(M) |

| 7 | Ball | A182 F304 | A182 F304 | A182 F304 | A182 F304 |

| Applicable medium | Water,steam,oil.,etc | Water,steam,oil.,etc | Acid.,etc | ||

| Applicable temp. | -29~425°C | -29~550°C | -29~200°C | ||

Dimensions(mm) and Weights(Kg)

| NPS | RB | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | / |

| SB | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | ||

| L | 92 | 111 | 111 | 120 | 152 | 172 | 200 | 220 | |

| W | 65 | 79 | 79 | 97 | 104 | 120 | 139 | 215 | |

| WT(kg) | BB | 1.6 | 3.4 | 3.3 | 5.5 | 6.0 | 9.2 | 12.9 | 16.2 |

| WB | 1.3 | 3.2 | 3.1 | 4.8 | 5.4 | 8.5 | 11.2 | 14.3 | |

Related Category

Ball Valve

Gate Valve

Check Valve

Solenoid Valve

Butterfly Valve

Other Valves & Parts

Control Valve

Globe Valve

Safety Valve

Angle Valve

Pressure Reducing Valve

Diaphragm Valve

Needle Valve

Exhaust Valve

Plug Valve

Steam Trap

Inlet Valve

Sampling Valve

Mini Pressure Valve

Blind Valve

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.